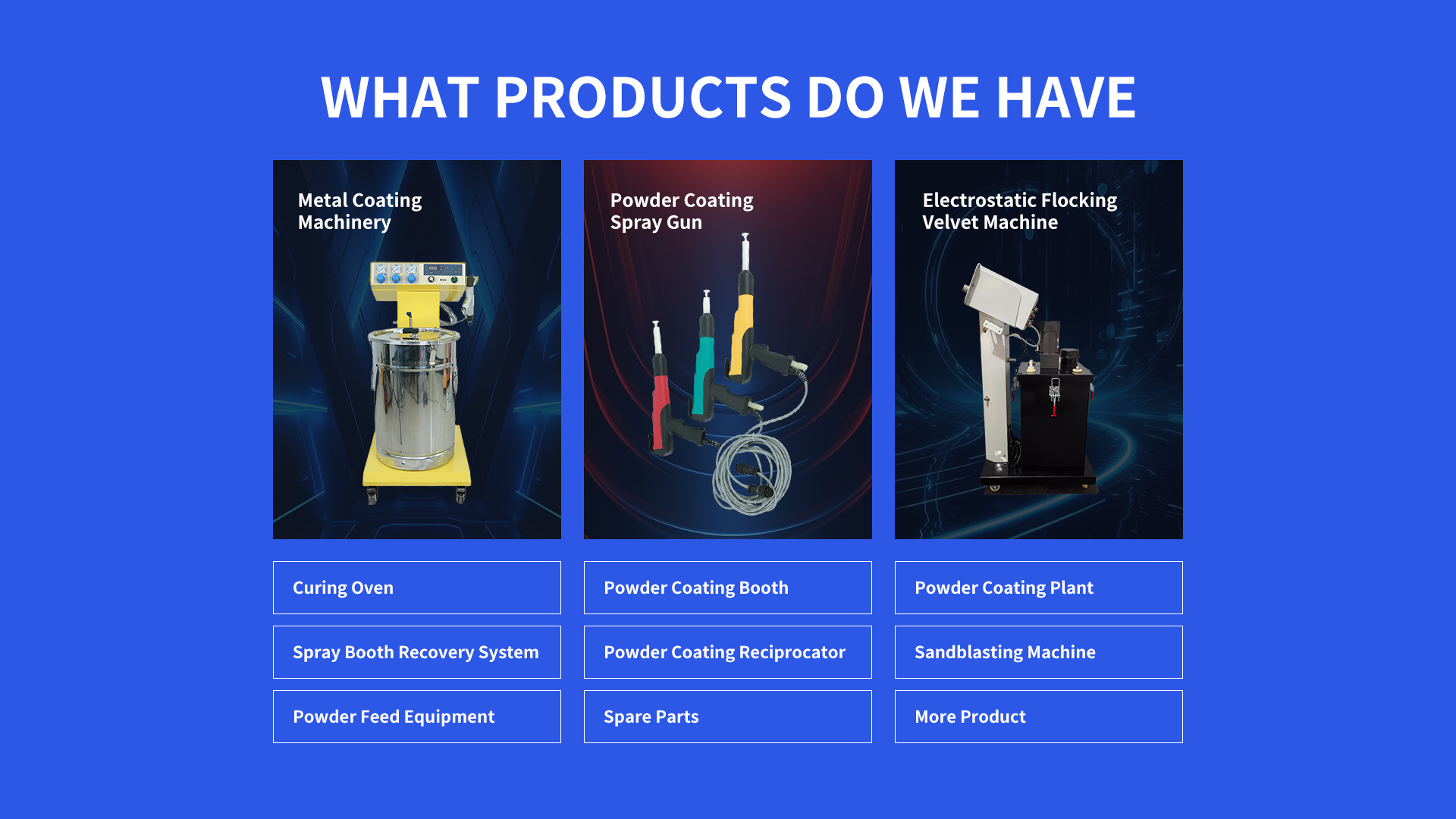

1. Plastic Powder Coating Booth Overview

A Plastic Powder Coating Booth is a specialized workspace designed for applying powder coatings to non-conductive materials (plastics, composites, MDF). Unlike metal coating booths, these systems incorporate:

Pre-treatment zones for surface activation

Static control systems for plastic adhesion

Low-temperature curing options (120-200°F)

Critical for industries requiring durable plastic finishes without warping or deformation.

2. Key Applications

✔ Automotive interiors (dashboards, trim)

✔ Consumer electronics (laptop casings, TV bezels)

✔ Medical equipment (device housings)

✔ Architectural composites (synthetic panels)

✔ Furniture manufacturing (laminate surfaces)

3. System Components

| Component | Purpose |

|---|

| Plasma/Corona treater | Pre-charges plastic surfaces |

| Conductive primer station | Enhances powder adhesion |

| Low-voltage electrostatic guns | Prevents material damage |

| IR curing zone | Gentle heat for thermoplastics |

| Anti-static air filtration | Removes stray particles |

4. Price Range (New Equipment)

| Booth Type | Price Range | Best For |

|---|

| Basic manual | 15,000−35,000 | Prototyping/small batches |

| Semi-auto | 40,000−80,000 | Mid-volume production |

| Full auto | 100,000−250,000+ | High-volume lines |

Cost Factors:

Size (small 4'x4' booths vs. conveyorized systems)

Pre-treatment method (flame vs. plasma)

Curing tech (IR vs. convection)

5. Step-by-Step Plastic Coating Process

Surface Cleaning – Remove mold release agents

Pre-Treatment – Plasma/flame activation

Priming – Apply conductive coating (optional)

Powder Application – Low-voltage electrostatic spray

Curing – 120-200°F for 5-15 minutes

Cooling – Controlled ambient cooling

6. Critical Buying Considerations

✓ Material Compatibility – Confirm booth works with your plastic (ABS, PVC, Nylon, etc.)

✓ Temperature Control – Must stay below material distortion point

✓ Static Management – Look for ionized air systems

✓ Safety Certifications – UL, CE, and NFPA for plastic dust hazards

7. Maintenance Checklist

Daily:

Weekly:

Monthly:

8. Top Manufacturers

| Brand | Specialty |

|---|

| Nordson | High-end automated systems |

| Wagner | Budget-friendly manual booths |

| ITW Gema | Hybrid metal/plastic solutions |

| Plasmatreat | Best plasma pretreatment |

9. Plastic vs. Metal Coating Booths

| Factor | Plastic Booth | Metal Booth |

|---|

| Voltage | 10-30kV | 30-100kV |

| Curing Temp | 120-200°F | 300-450°F |

| Pretreatment | Plasma/flame required | Usually just cleaning |

| Powder Types | Special low-temp formulas | Standard powders |

10. Troubleshooting Guide

Problem: Poor Adhesion

➔ Solution: Increase plasma treatment time

Problem: Surface Warping

➔ Solution: Reduce IR curing temperature by 10%

Problem: Static Clumping

➔ Solution: Recalibrate ionizing bars

Problem: Inconsistent Finish

➔ Solution: Verify gun distance (8-10" ideal)

11. Future Trends

UV-curable powders – Eliminates heat distortion

AI pretreatment – Auto-adjusts plasma for material type

Conductive polymers – May eliminate priming step

This guide equips manufacturers with actionable knowledge for implementing plastic powder coating solutions, from small shops to full production lines.

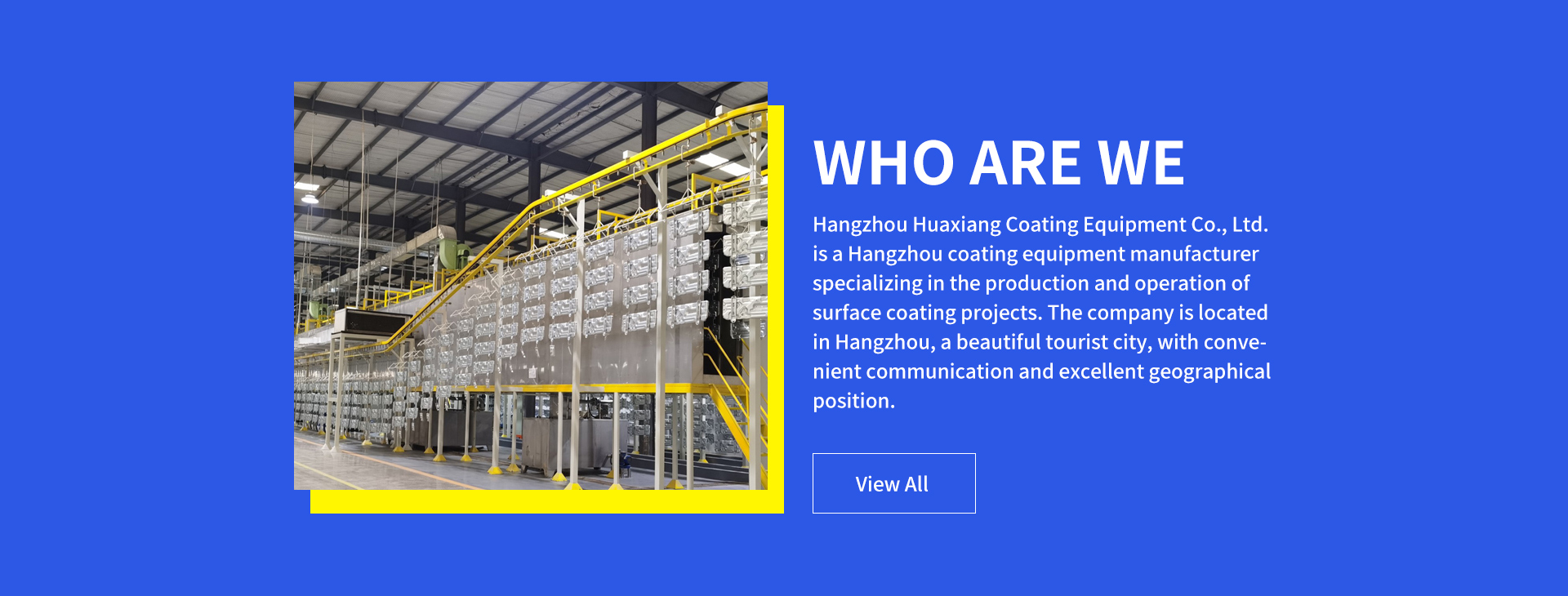

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com